| QGM | QFM | HXM | Ruitu | Honchan | HDM | Sanlian | HongFa |

| Dekeda | Donyue | HYM | HuaTong | Noah | XieXing | XiangDa | ShengYa |

| HuaYuan | FuLang | ZCJK | ONNOH | HUONSS | YiXin | HongYi | XiongHui |

-

AAC block machine China Autoclaved Aerated Concrete Block Machine Suppliers

Autoclaved Aerated Concrete Block Machine Suppliers

3494 Views

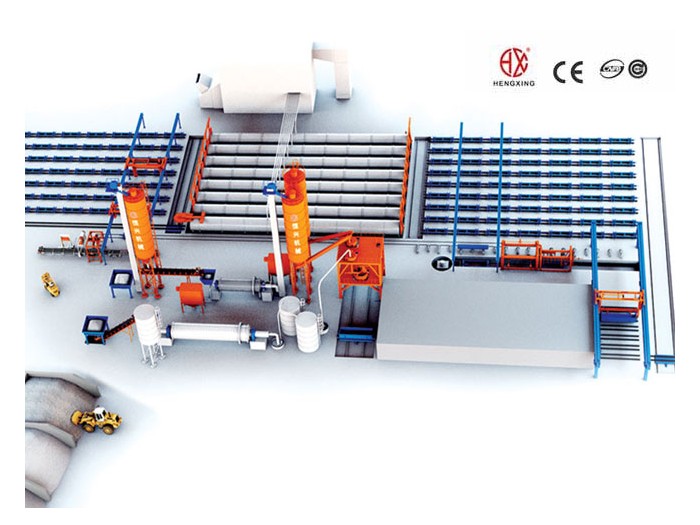

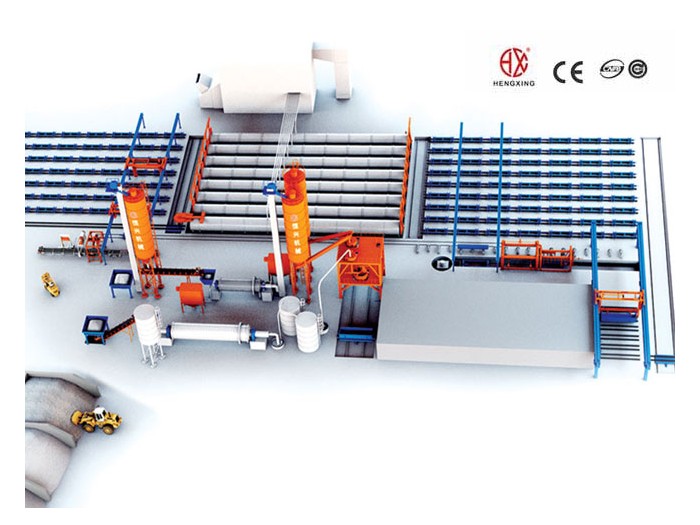

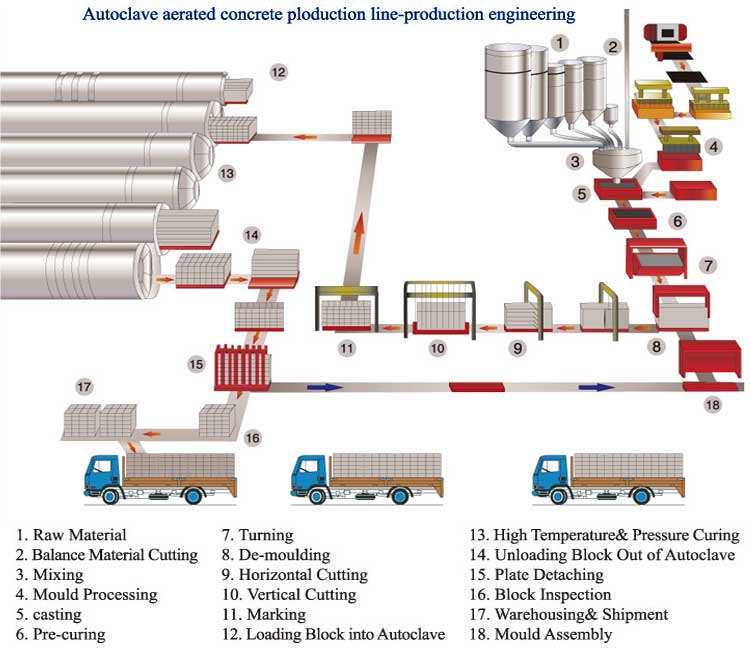

Autoclaved Aerated Concrete Block Machine Production Line (AAC) is a lightweight brick production Machinery and equipment, commonly known as aerated block device or aerated brick production line.

utoclaved Aerated Concrete Production Line (AAC) is a lightweight brick production machinery and equipment, commonly known as aerated block device or aerated brick production line. It is based on cement, lime, slag, fly ash, sand, hair air materials as raw materials, grinded ingredients, pouring, cutting, steam curing conservation and milling processes made of. After gas evolution because of its internal product contains a lot of uniform and fine pores, hence the name of aerated concrete block. It is light weight, good insulation properties and processability, etc.,

it is to promote the application of the earliest and one of the most widely used lightweight wall materials, good prospects for development. Aerated concrete equipment came into being to meet the needs of the market. Fujian hengxing Machinery Company always adhere to the "quality first, the credibility of the first" principle, strive to provide quality and efficient steam-cured aerated concrete equipment.

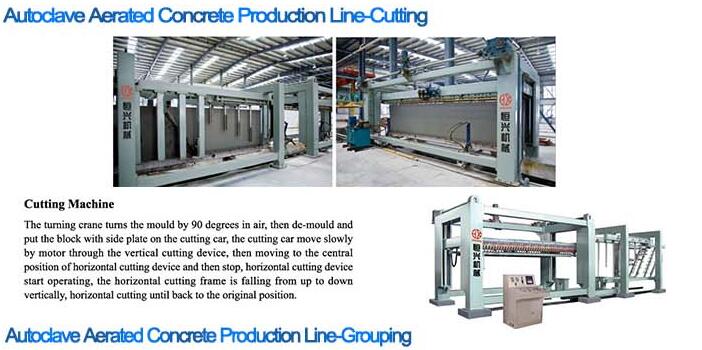

fully automatic cutting machine is consist of vertical cutting machine and horizontal cutting machine. After the pouring Aerated concrete will become a formed cake after pre-curing. The cake will be cut into the exact size according to user's requirement.

Working Principle:

Turning sling turned over 90 degrees, parting the body along with mold side plate placed on the cutting car, cutting car through the motor start walking slowly through the launch of slitting device after slitting, cutting car walk to the horizontal crosscut device the central position and stopped, crosscutting device starts, crosscutting top-down vertical landing, horizontal cutting until reset.

Technical Parameters:

No. | item | unit | index | note |

1 | capacity | 10,000m3/year | 10-30 | annual output |

2 | size | M | 6×1.2×0.6 | net |

3 | module | mm | 5/10 | vertical/horizontal |

4 | cutting accuracy | mm | ±3±1.5±1.5 | L.W.H |

5 | production cycle | min/mould | 6 | |

6 | weight | t | vertical/horizontal | |

7 | installed power | kw | 12.9 | included hydraulic unit |

Ball Mill for AAC Equipment

Ball mill is the critical equipment for the broken material being smashed, Aerated brick ball ill is widely used in cement, Portland products, new building materials, Refractory, fertilizer,black and nonferrous metal ore dressing and glass ceramics production industry, for all kinds of ores and other grinding materials.

weighing scale-weighing system for AAC block making machine

Weighing Scale-Weighing System

Raw material grinding to the slurry has realized the automatic control of domestic control system running stable and reliable,

casting quality is stable, conveniently adjustment, is advantageous to the concrete product quality and

to increase the utilization rate of equipment.

working process as follow:

Raw materials tanks, cement, lime, plaster through screw conveyor to dry material measurement, the proportion of

all kinds of raw materials can be used to accumulate measuring by semiautomatic control system, also can use the automatic

PLC control system for automatic additive weighting. fly ash or sand slurry by pouring through the pipe directly to the floor of pulp weighing hopper, this measurement can also be divided into automatic and semi-automatic measurement.

after the measurement of this three kinds of material and slurry through screw conveyor pouring agitation to tank for mixing,

and aluminum powder will be added by manual weighing.

Features Demands:

Pouring floor construction can be divided into the reinforced concrete structure and steel welded structure,

the general design principle is the pouring floor weighing capacity must reach more than 200 tons, raw materials tank can bear the extra weight.

Specific Equipment Composition

(1) pouring tower frame (3 layers)

(2)cement hopper

(3)lime hopper

(4)gypsum hopper

(5)weighing scale

(6)slurry scale

(7)screw conveyor

(8)pouring mixer

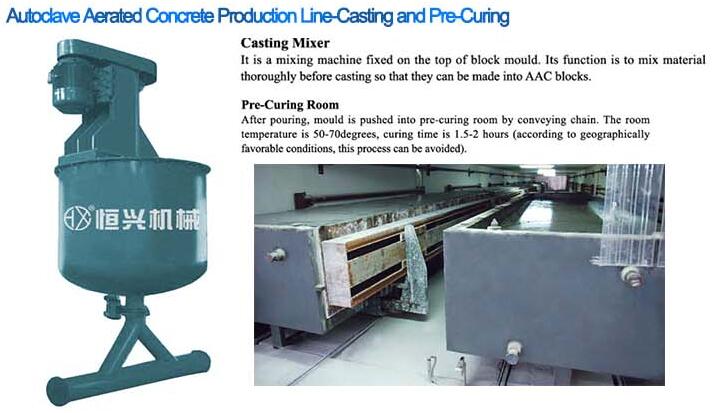

casting mixer for Autoclaved Aerated concrete block machine(AAC)

Casting Mixer for AAC Equipment Compose of mixing drum, motor,pouring arm, thermometer, stirrer, pneumatic butterfly valve,etc.

products introduction:

1. Compose of mixing drum, motor,pouring arm, thermometer, stirrer, pneumatic butterfly valve,etc.

2. requirements:

2.1.The way of draft tube (22kw motor power)..

2.2. Meet the cutting capacity.

2.3. high performance (do the test of balance)

2.4. Stirring fast, well-distributed.

3. technical parameters:

4.2 m3 effective volume

∮1700mm inner diameter

∮640mm blade diameter

460r/min speed

22KW power

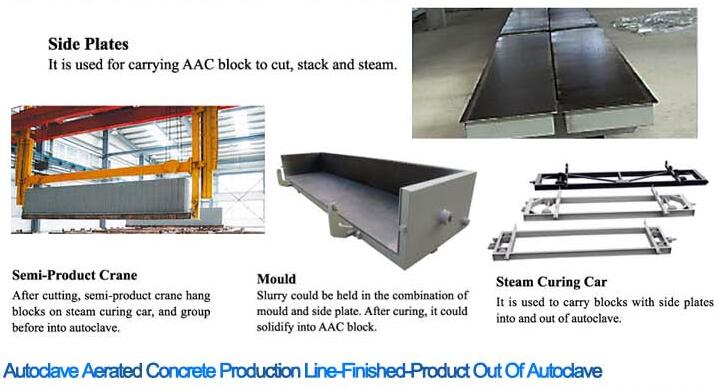

mould and side lining panel for AAC block machine production line

Mould compose of model frame, underframe, clamping device, carriage wheel, seal strip.

Side lining panel compose of inner plate, outside plate and upright.

mould car/4.2m mould side lining panel

1. Mould side lining panel composition

Mould compose of model frame, underframe, clamping device, carriage wheel, seal strip.

Side lining panel compose of inner plate, outside plate and upright.

2. mould, side lining panel requirements

2. 1. Mould and side lining meet the needs level 07 products.

2. 2.Mould, side lining panel interchangeability.

2. 3. easy parting,reassembly when combination .

2. 4. Mold side panel in body contact error≤1mm/m, side panel winding degree≤1mm/m.

2.5. meet the net size of cut body 4200*1200*600mm.

2. 6. Mould inside and the edge chamfer grinding to the flat, to promise no arris defect.

2. 7. The side panel adopts the quality steel products, weldment deformation≤1%,

make the side panel deformation to a absolute minimum.

3. 4.2×1.2×0.6m net side

4. Mould clamping device, minimum usage≥3000 times.

Technical Parameters:

dimension | casting body | max size(mm) | body/mould (m3) | ||||

L(mm) | W(mm) | H(mm) | L (mm) | W(mm) | H(mm) | ||

4.2*1.2*0.6 | 4200 | 1200 | 600 | 4720 | 1735 | 1078 | 3.024 |

4.8*1.2*0.6 | 4800 | 1200 | 600 | 5320 | 1735 | 1078 | 3.456 |

6.0*1.2*0.6 | 6000 | 1200 | 600 | 6550 | 1750 | 1085 | 4.320 |

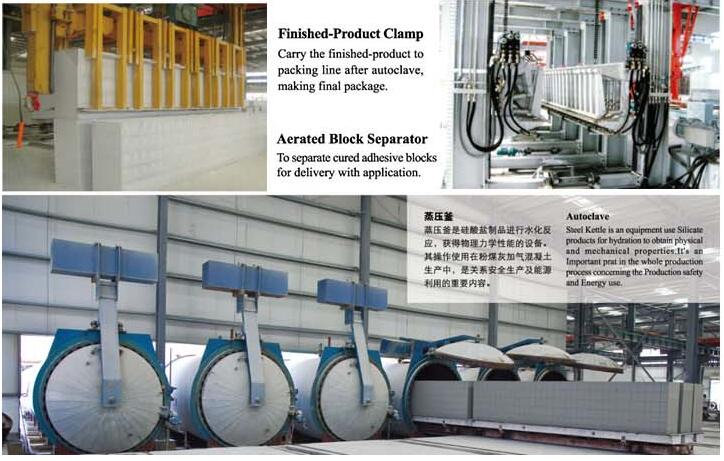

autoclave for AAC Equipment

Autoclaved kettle is large container equipment, for lime-sand brick, brick of fly ash aerated concrete block, new type of light wall materials, autoclaved curing concrete pipe pile and other building products, through the curing, make the products get high strength.

Products Introduction

kettle length, gauge size in the kettle, open form of kettle door.

Uses and Features:

Autoclaved kettle is large container equipment, for lime-sand brick, brick of fly ash aerated concrete block, new type of light wall materials, autoclaved curing concrete pipe pile and other building products, through the curing, make the products get high strength. Currently products in addition to used in silicate building products, also used in chemical ,medicine, rubber, timber, plaster, glass, thermal insulation material, military, industry and other fields.

The product learned abroad the most advanced design concept, combining with the characteristics of the domestic pressure vessel production, design and manufacture in accordance with professional standards and procedures structure is reasonable. There are different forms of flexible operation Safe and reliable product---autoclaved kettle.

Don't forget to leave your phone number and email, we will reply you as soon as possible!

Inquiry message list :