| QGM | QFM | HXM | Ruitu | Honchan | HDM | Sanlian | HongFa |

| Dekeda | Donyue | HYM | HuaTong | Noah | XieXing | XiangDa | ShengYa |

| HuaYuan | FuLang | ZCJK | ONNOH | HUONSS | YiXin | HongYi | XiongHui |

-

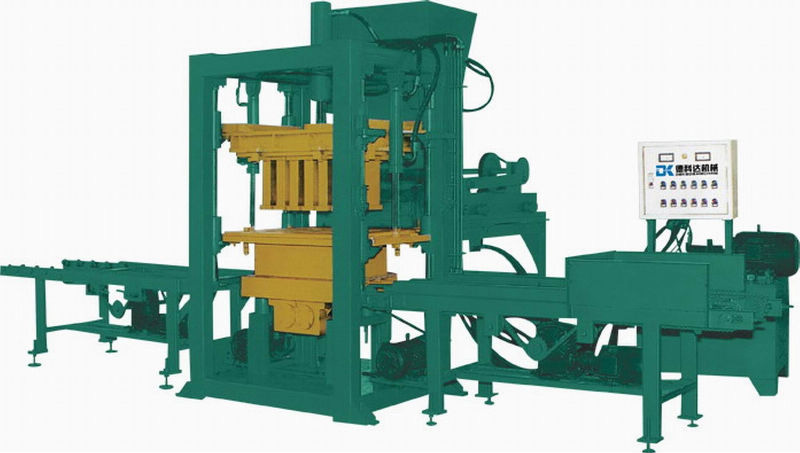

DK3-20 Block Making Machine

Dekeda machinery DK3-20 Block Making Machine

2227 Views

QGM QT6 fly ash brick machine

- 2918 Views$US

Sanlian QT6-15 Block Making Machine

- 2280 Views$US

Noah QT4-30 BLOCK MAKING MACHINE

- 2925 Views$US

HXS1100 Hydraulic Pressure Block Machine

- 2421 Views$US

Full Automatic block making machine

- 4298 Views$US

HQTY10-15 concrete brick machine

- 2421 Views$US

1. Technical Data

| Model | DK3-20 |

| Pallet Size | 680*530mm |

| Control System | PLC auto computer control |

| Circle time | 20-30s |

| Installed capacity (KW) | 18.5kw |

| Machine Weight | 3500kg |

2. Production Capacity

| Specification of production | Qty of blocks per pallet | Pcs/hr | Pcs/8hrs | Pcs/300days (two shift) |

| Hollow block 390*190*190mm | 3 | 360 | 2880 | 1,728,000 |

| Multicellular bricks 240*100*60mm | 10 | 1200 | 9600 | 5,760,000 |

| Paving bricks 200*100*60mm | 15 | 1800 | 14400 | 8,640,000 |

| Standard bricks 240*115*53mm | 20 | 2400 | 19200 | 11,520,000 |

1. Brief introduction

Brick Making Machine is the core machine used for producing blocks/bricks. The technology is introduced from German Hess. This machine is automatic and multi-functional. It can produce large varieties and various sizes of products, including concrete blocks, bricks, hollow block, insulated block, solid bricks, paving slabs, interlocking pavers, paving stone, retaining stone, curb stone etc..

2. Characteristics

1. Our machine has harmonic cooperation between mechanical, hydraulic and electrical machines functions, guarantees a stable and reliable performance.

2. Central control system: full automatic computer control, easy man-machine interaction, the production data feedback in real-time, customized setting allows user to operate in Full automatic / semi-automatic / manual modes, adapts to complex working conditions and enabled to long-range control and maintain, quicken after-sale service efficiency and quality.

3. Components: all core parts adopt international well-known brand ( Siemens Motor, NSK bearing, Panasonic transducer, Ormon Button, PLC sensor), reduce maintenance cost and increase the lifespan of brick machine.

4. Uses Germany frequency conversion technology: automatically adjust the most suitable working speed, guarantees the precise and parallel movement and improve the product density and save more than 20% energy.

5. Rods guiding feeding system: the skip moving adopts rod guiding+leather sheath, feeding stably and evenly, with no rigid shocking to machine body. Uses 360° multi-shaft rotating and compulsory feeding, greatly improves the density and intensity of the blocks and reduces the feeding time.

6. Vibration system: uses latest developed vibrating system, guarantees amplitude and high equilibrium vibration, ensure the uniformity of finished brick. Separated structure of vibration table and machine, besides using rubber mat also add gas device to concentrate vibration in the table and moulding platform, to maximize reducing the vibration passed to machine.

7. Hydraulic system: hydraulic pump and valve all adopts international top brands and matching with air cooling and water-cooling system to enhance heat dissipation. The oil tube joint use double sealing design, reduce the oil leakage in high temperature condition.

8. Frame design and processing: the whole frame use Q345 high-intensity steel and special welding technology. The four guide column locating and assembling with unique technique fitting, prolong the lifespan of machine.

9. Stable pressure head: adopts gear synchronous and locking device, guarantees the uniformity of brick and the security of whole machine.

10. The mould is casted with internal steel and processed by computer controlling, the size is precise and error free. Use heat and carburizing treatment, greatly improves the using lifetime of the machine by 50%.

Don't forget to leave your phone number and email, we will reply you as soon as possible!

Inquiry message list :